Products >> Labeling Machine >> Horizontal way labeling machine

Vial labeling machine

- Product No.:BE-S-H-100

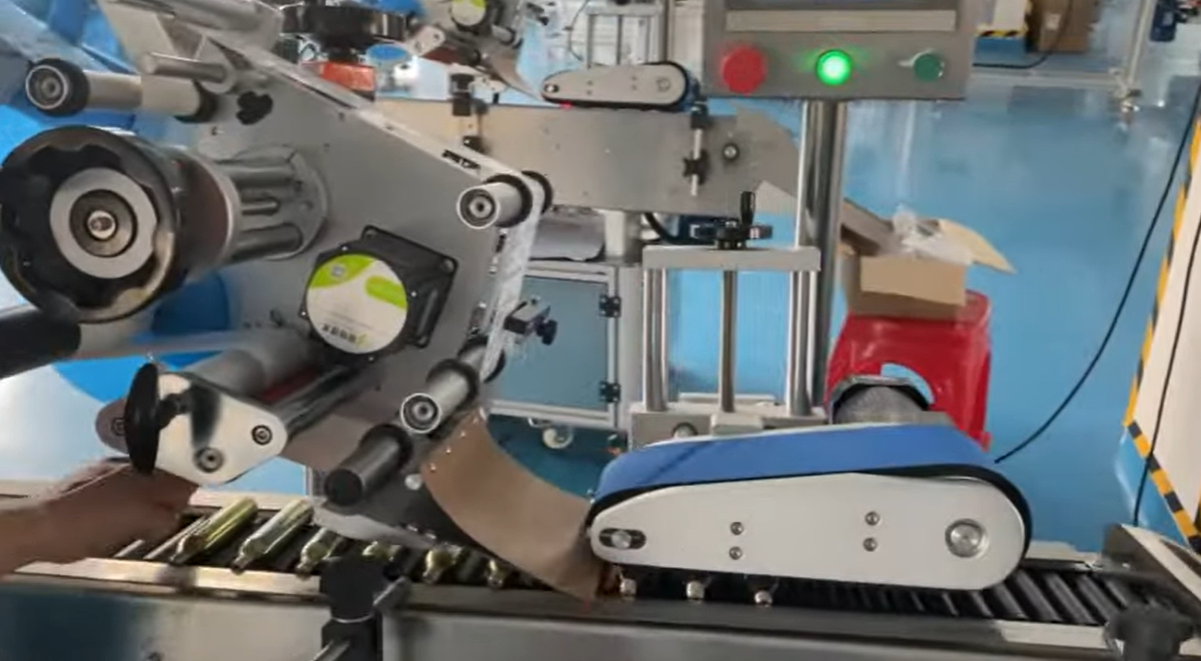

Vial labeling machine

Machine introduction:

1. Equipment composition: electrical cabinet, labeling engine, bottle splitting mechanism, conveying mechanism, marking mechanism, pneumatic coding mechanism (standard), operating system and control system.

2. Control system: Japan Mitsubishi/Japan Panasonic control system, with high stable operation and extremely low failure rate;

3. Operation system: Touch screen, with Chinese and English language, rich with help function and fault display function,easy operation;

4. Check system: label sensor, automatic check label position, stable and convenient don't have much higher requirement for the worker skill;

5. Send label system:Servo/Step motor control system, stable with high speed;

6. Alarm function: such as label spill, label broken or other malfunction during machine working all will alarm and stop working.

7. Machine Material:The machine and spare parts all use material S304 stainless steel and anodized senior aluminum alloy,with high corrosion resistance and never rust;

8. Low voltage circuit all use the France Schneider/Panasonic brand.

Feature:

Vial labeling machine is used for the surface labeling of the round objects in such industries as medicine,daily chemical,food and so on.It can posted single label.

Parameter:

1.This machine can label test tubes, blood collection tubes, droppers, round tubes, ham sausages etc. with self-adhesive labels.

2. Composed by main body, sending paper, receiving paper, product orientation etc parts.

3. Putting the ampoule、tube、vial、pen、Lipstick、sausage to orientation part by manual and fix the positon;

4. This machine is CE certified.

Workflow:

1. The object is fixed with the same center line to move forward at the same time after dividing distance through the bottle splitting mechanism;

2. When the photoelectric sensor detects the object, the labeling engine starts to work, and the driver drives the motor to rotate and pull the label. The coding machine prints the label in three phases. Label inspection photoelectric work (when the gap between the label and the label is detected), the labeling engine stops working, and the label stripping board strips the label and pastes it to the surface of the product, and then the material rotates through the label rolling device to smooth the bottle label;

3. After labeling, the label flows into the next process.

Manufacturing Technique

|

Model |

BE-S-H-100 |

| Labeling speed |

60-400pcs/min |

| Labeling accuracy |

±1mm |

|

Labeling positon |

Wrap around |

|

Suit label size |

Width 10-100 mm length 10-150 mm |

|

Suit product siz |

Can customized depends on product |

| Inner diameter of label roll |

76 mm |

| Outer diameter of label roll |

350 mm(max) |

|

Weigh |

220kg |

|

Power |

220V,110V,50Hz,1Kw,0.6Mpa |

| Machine size |

1800(L) 800 (W) 1300 (H) mm |

The following products are suitable for horizontal way test tubes, blood collection tubes, vial,ampoule,droppers, round tubes, ham sausages and other products that cannot stand up.

|

|

|

|

|

|

Products Category

Contact Us

Name: vivian

Mobile: +86-18939808662

E-mail: sales@beiltmachinery.com

WeChat: +86-18939808662

Whatsapp: +86-18939808662

Add: No. 1990 Jinbi Road, Jinhui Town, Fengxian, Shanghai, China.

WhatsApp

WhatsApp  Mail inquiry

Mail inquiry